|

|

|

![]()

Since 2010, more or less, increasing numbers of bicycles have been sold with forkends that have holes rather than slots, and with “thru axles”, rather than quick-release assemblies. Why is this? Let’s make a comparison and see why.

A quick-release assembly slides into a hollow axle and clamps against the dropouts.

The axle of a quick-release hub extends into the dropouts to align the wheel. A quick release assembly inserts into the axle, which is hollow, and compresses the dropouts against the hub locknuts. When the quick release is properly tightened, the axle does not bear against the top of the dropout slot to resist the load on the hub. Rather, the locknuts press hard against the inner faces of the dropouts and transmit all of the forces to the fork or frame. More about quick releases is here.

A traditional quick-release skewer is 5 mm thick, though some are 9 mm thick.

Traditional hub locknuts are serrated (have teeth) so they bite into the dropouts. If the quick release is tightened properly onto steel, titanium or aluminum dropouts, the locknuts can support any normal load, even the chain tension from a tandem bicycle – except for the loading from a front disc brake.

A thru axle is thicker than a quick-release skewer. The thru axle inserts into the hole in (usually) the left front or rear forkend, passes through the hub, and screws into a threaded hole or in the other forkend, or a frame fitting. The forkends may have shallow recesses to align the wheel as it is inserted, but no part of the hub extends into the holes in the forkends. It couldn't: the hub could then be inserted only by prying the forkends apart!

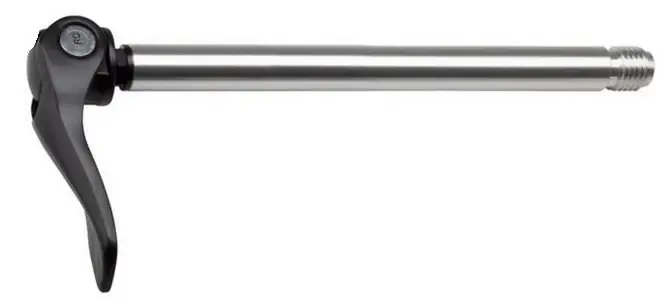

This thru axle screws in like a bolt.

A tool, usually an Allen wrench, is needed to install or remove the type of thru axle shown in the image above. This kind of thru axle is a bit more convenient than a nutted axle, as it is tightened from only one side.

A thru axle may be tool-free, with a cam assembly like a quick release. This type is somewhat more convenient than a quick-release assembly with a front fork that has "lawyer lips". The thru axle must be adjusted every time it is installed, but there is no need to reach around the wheel to an adjusting nut. There are various ways the lever is released once the axle is secured, to allow the lever to rotate to a preferred orientation.

This thru axle screws in like a bolt and tightens like a quick release.

Some thru axles have a lever to spin them, without the quick-release clamping action. Again, the lever can release to rotate to a preferred orientation..

DT Swiss thru axle with pushbutton-releaseable lever.

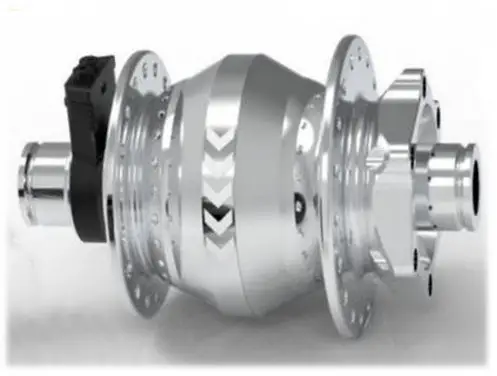

The bearings of a thru-axle hub rotate around a sleeve that encircles the thru axle. This sleeve is like a large-bore version of the hollow axle of a quick-release hub, except that it does not extend into the forkends. With most thru-axle hubs, radial loads (weight, chain tension and loading from braking or pedaling) are mostly taken up by the thru axle rather than being transferred to the forkends by the surfaces at the ends of this sleeve. The sleeve is kept from rotating by the compression of the thru axle.

Most thru-axle hubs use cartridge bearings. A hub bearing is behind the dark circle in the image below, which is the bearing seal. Shimano uses cup-and-cone bearings, as with other Shimano hubs.

The images that follow are of generator hubs, as they have a special issue with thru axles. We'll get to that, but otherwise they work the same as other hubs with thru axles.

End view of a hub made for a thru axle

Hubs can adapt to different thru axles as long as the dimensions are correct.. The usual thickness of a thru axle is 12 mm, though some Shimano E-Thru axles are 15mm and some thru axles for demanding applications are 20mm. Hub/spacing width and thru-axle threading may differ, and the seat for the bolt head/lever end may be flat or tapered.

![]()

![]()

A Shutter Precision disc-brake front generator hub with a quick-release axle.

The axle extends into the front fork's dropout's slots.

The hub faces press against the dropouts.

A similar hub for a thru axle.

Issue: the axle can feel secure, yet the sleeve can rotate around the axle.

You may also view a Global Cycling Network video about how to use a thru axle.

The trend toward thru axles arose due to several factors:

![]()

![]()

A thru axle system does have some important disadvantages.

![]()

![]()

To sum up, I advise that bicycles with disc brakes have thru axles, at least for the front wheel, because they solve the safety issue. Thru axles also improve the stiffness of suspension forks. But thru axles bring problems of their own, and if you are a retro-grouch like me, you'll stick with quick releases and rim brakes, or you'll pay close attention to the tightness of quick releases on bicycles with disc brakes, indeed, I have two of them!

Thanks to Robin Schulman for help with this article.

![]()

![]()

Last Updated: by John Allen