|

|

|

Most bicycle chainrings have between three and six bolt holes to attach them to the crank, spaced around a bolt circle. This page describes details of bolt-hole patterns in connection with our chainring bolt-circle cribsheet

A chainring and crank with different bolt-hole patterns are definitely not compatible, but the bolt-hole pattern doesn't tell the whole story about compatibility if you mix and match parts. Bolt-hole size, threading, tooth thickness, ramps and pins may differ. Sometimes you can solve a problem by installing a chainring inside-out, using washers to adjust spacing, or drilling out bolt holes. Check for these issues:

After determining the BCD, you might check Wolf Tooth's Road and MTB chainring entries for details on newer 4- and 5-bolt chainrings; also RaceFace's compatibility table. Wolf Tooth offers a guide to direct-mount (spiderless) chainrings at the bottom of a page on its Web site.

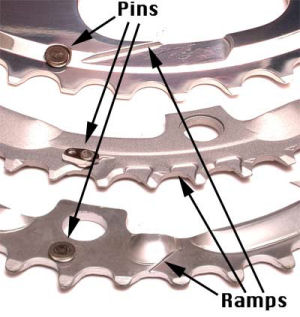

All chainrings used to have bolt holes evenly spaced around the bolt circle. Starting around 2010, manufacturers introduced patterns with unevenly-spaced holes. These allow bolt heads of a small-diameter pattern to clear a thick crank, and enforce chainring orientation, important with chainrings that have ramps and pins to make shifting smoother.

Power from pedaling has two peaks and two dips per rotation. Unevenly-spaced bolt holes prevent reorienting chainrings to increase wear life. Some patterns produce "brand lock" while others are available from more than one manufacturer. Wolf tooth explains it CAMO pattern compatible with no others, in this way:

The CAMO chainrings will only fit in one orientation and with the right side facing out so people can't accidentally mount an oval chainring in the wrong orientation or have asymmetric chainring teeth running backwards. The other important note on CAMO is that it doesn't use conventional chainring bolts.

Wolf Tooth and FSA make chainrings to fit other manufacturers' cranks as well as chainrings that fit only their own cranks. Please see the page at pardo.net discussing technical, pricing and availability issues for chainrings with unevenly-spaced bolt holes.

Bolt-hole spacing dimensions given here for evenly-spaced holes reflect exact angles calculated using trigonometry. For unevenly-spaced holes, we have used dimensions reflecting an integer number of degrees, and some have yet to be confirmed. Measured angles for all Shimano unevenly-spaced holes of 4-bolt chainrings were so near 70 and 110 degrees that our numbers are almost certainly correct. SRAM had to be different, and its angles appear to be 72 degrees (same as with a 5-bolt chainring) and 108 degrees. And similarly with Campagnolo, 80 and 100 degrees and different bolt-circle diameters.

If you can provide corrections or additional information, please do! A Microsoft Excel workbook with calculations of all the dimensions used on this page is available on this site.

Many thanks to Ulrik Hansen and Samuel He for updates to the 4-bolt crank list, and to Wolf Tooth for confirmation of CAMO dimensions.

![]()

![]()

Many newer chainrings have unevenly-spaced bolt holes, the main reason for new entries in our list. There are a couple of good reasons for uneven bolt-hole spacing:

But there is also brand lock when different manufacturers adopt different specifications. And a couple of technical problems also result:

Introducing a novel bolt pattern is easier than it once was .Chainrings used to be stamped out in a huge punch-press machine, like cookies with a cookie cutter, then lightly milled to reduce the thickness of the teeth and to drill mounting holes.  A large number of chainrings had to be produced in each size to justify the tooling cost, but unit cost was low. Now, on the other hand, anyone with computer-aided design software and a computer-aided milling machine can establish a new bolt pattern at low cost -- but the unit cost is higher.

A large number of chainrings had to be produced in each size to justify the tooling cost, but unit cost was low. Now, on the other hand, anyone with computer-aided design software and a computer-aided milling machine can establish a new bolt pattern at low cost -- but the unit cost is higher.

The popularity of multi-speed 1X ("one-by") systems -- those without a front derailer -- also has led to innovation. In a 1X system, the wider space between the outer plates of a chain lets every second chainring tooth be wider, offering some advantage in preventing the chain from coming off, and in the wear on the sides of teeth being taken by twice as many teeth. There is no additional bearing area for chain tension though, as the rollers of the chain have to fit between the inner plates. Chainrings with wide-narrow teeth are possible only with even numbers of teeth, and are practical only in a 1X system, because a chain could land the wrong way when shifted.

All in all though,fewer bolt patterns are currently made the early 21st century than in the mid-to late 20th century, as many legendary manufacturers have dropped out of the market, been bought up, or adopted bolt hole patterns from the largest manufacturers..

![]()

![]()

I started my work reviewing the bolt-circle diameter table by reviewing the entries with known bolt-circle diameters and evenly-spaced holes. Their spacing can be determined with trigonometry. I found small errors in published distances on our list and in other references. Evidently, people had taken measurements and never checked them with math. I corrected errors where I found them.

For uneven patterns, measurement and calculation are more complicated. Buying a sample of every kind of chainring would have bankrupted me. So, for some chainrings, I had to use manufacturers' specifications, or reverse-engineer geometric constructions from manufacturers' photos. This is trickier. How can it be done?

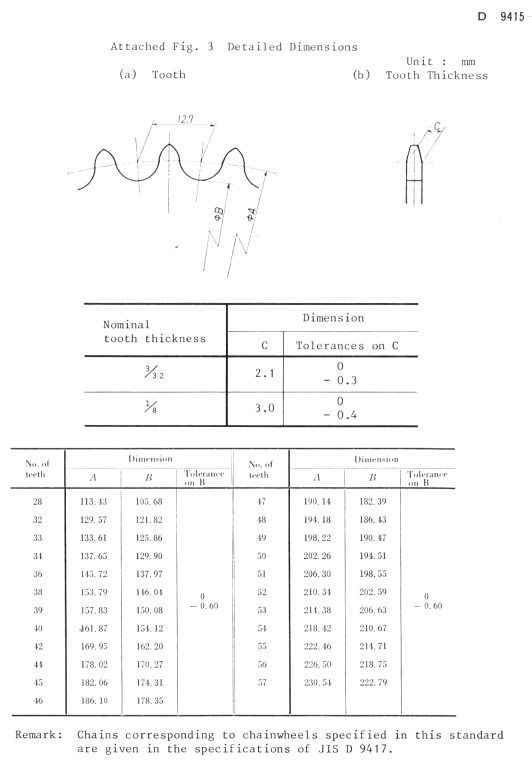

While bolt-circle diameters vary, the geometry of the tooth circle of all round bicycle chainrings adheres to a fixed pattern, as the pitch of the chain and the diameter of its rollers are the same. The tops of teeth may stand at different heights, but the gaps between teeth are at the same diameter, within tight tolerances, for any chainring with the same number of teeth. The diameter between gaps opposite one another may be calculated based on the dimensional standards, and he correctness of the calculation may be confirmed by measuring an actual chainring with an even number of teeth. I did both and checked with a 1982 Japanese Industrial Standards manual. You may find my calculations in the Microsoft Excel workbook here. And here is the page from the JIS manual.

![]()

![]()

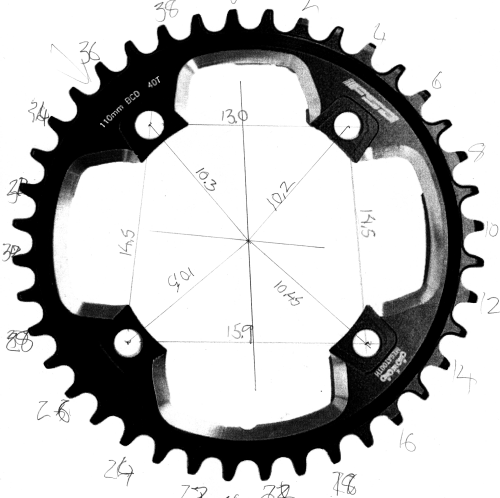

To find the bolt-circle dimensionspf a dhainring, I copy the manufacturer's photo of it onto a letter-size sheet of paper, as large as I can make it. To confirm that the plane of the camera sensor was parallel to that of the chainring, I find the center -- the intersection of two lines between opposite points on the chainring. This is easy if the chainring has an even number of teeth. Placing a straightedge at the edge of opposing teeth makes for high accuracy. Then I measure the distance out to the bolt holes from the center. If the camera sensor and chainring plane were parallel, radial distances will be the same. Most chainrings have all bolt holes at the same radius, making it possible to take an average. If the differences among measured radii are at all substantial, I reject the photo.

Having confirmed that a photo is usable, I draw the polygon connecting the centers of the bolt holes, and measure the lengths of the sides. For the sake of accuracy, I measure from right side to right side or left side to left side of holes, not between the centers.

If the manufacturer has not given the bolt-circle diameter, I need to determine it. Having established the diameter at gaps between teeth in the photo, I also measure the radial distance inward from the bottom of a gap between teeth to the center of a bolt hole. The ratio between the measurement in the photo and the calculated dimension establishes the scale of the photo. The image below gives an example of this geometric construction.

The bolt circle diameter at the scale of the photo is the distance between gaps, minus twice the radial distance from a gap to the center of a bolt hole. I determine the bolt-circle diameter by multiplying by the ratio of actual spacing between gaps to the one in the photo.

The image below shows my measurements of a photo of a Wolf Tooth CAMO series chainring, which has subtly uneven bolt-hole spacing. I calculated the bolt-circle diameter and angles of the bolt holes based on measurements like the ones shown, using photos of several CAMO chainrings on the Wolf Tooth Web site.

Having done this for several chainrings with the same bolt-hole pattern, I can take an average, and then make an adjustment based on the probability that bolt holes are spaced at integer numbers of degrees from one another.

I sent results to Wolf Tooth and received confirmation that they were correct, validating my method and allowing me to trust it as I applied it to other chainrings. I found a few measurements of other chainrings with unevenly-spaced bolt holes on the Wolf Tooth site which further confirmed my measurements.

If the manufacturer has given the bolt-circle diameter, the task of measurement is easier. The scale of the photo can be determined directly from the radii from the center to the bolt holes. The FSA chainring in the photos below is clearly marked as having a 110mm bolt-circle diameter.

Results of these calculations are on the bolt-circle diameter cribsheet page and in the templates which my son Jacob has generated and you can print out to check chainring dimensions.

![]()

![]()

Last Updated: by John Allen