|

Translations of this article (older version): German

|

|

|

Translations of this article (older version): German

|

|

This is the lead article about chainline. Read it in connection with one of these other articles:

The word "chainline" refers to how straight the chain runs between the front and rear sprockets. Ideally, both sprockets should be in the same plane, so that there is no sideward motion or stress to the chain. This constitutes "perfect chainline".

In the case of derailer geared bicycles, the chainline is not perfect in most gears. Chainline mismatch can cause the chain to rub against the side of an outer, larger chainring when engaged with a smaller one, and can cause problems with shifting, especially with the front derailer. The worse the chainline, the worse the mechanical efficiency of the drive train, though research has shown the loss to be minor, at least with modern, flexible chains.

"Correct" chainline for a derailer system is a matter of opinion, and depends on the intended use of the bicycle. There are two "simple" answers to the question of what constitutes proper chainline.

| Application | Dimension | Notes |

|---|---|---|

| Track/Coaster Brake Traditional One-Speed Most internal gear hubs |

40.5-42 mm | Older bikes with 110 spacing would be on the smaller end of this range Newer bikes with 120 mm spacing normally use 42 mm |

| Road Double | 43.5 mm | Shimano spec, measured to the midpoint between the rings. with typical 5 mm chainring spacing, this puts the inner at 41 mm, the outer at 46 mm. |

| Road Triple | 45 mm | Shimano spec, measured to the middle ring. |

| Singlespeed MTB Alternate |

47.5 mm | White Industries ENO hubs use this chainline, which lines up with the middle position of a typical MTB triple. It's also fairly close to the outer position of a typical "road" double. |

| MTB Triple | 47.5-50 mm | Shimano spec, measured to the middle ring. 47.5 preferred, but for frames with oversized seat tubes, the longer dimension may be needed, because the fat tube places the front derailer mechanism farther to the right. SRAM standard chainline is 49mm with 142mm OLD and thru axle |

| Singlespeed and Single-chainwheel MTB, "Boost 148" | 52 mm | Wider chainline need for chainstay clearance on newer MTBs, typically with disc brakes and 148 mm OLD spacing This is close to the chainline of the outer ring of a typical MTB triple. |

| Rohloff Speedhub | 54 mm (58 mm w/13 tooth) |

Sprockets are proprietary, threaded. All except the 13-tooth may be flipped over to double wear life. |

| Freeride and Downhill | 55 mm | Newer Freeride and Downhill bikes with 150 mm spacing |

| Tandem | about 60 mm | Tandems with 160 mm spacing |

| Fatbike | 66 mm | Fatbikes with 170 mm spacing |

| Fatbike | 76 mm | Fatbikes with 190 mm spacing -- needed with 4.8" (125 mm) wide tires. |

![]()

![]()

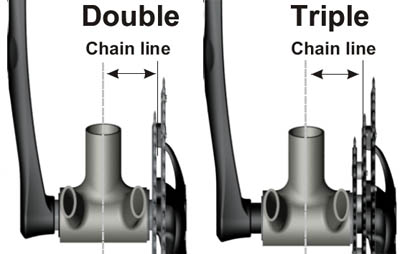

Chainline is measured from the centerline of the frame to the center of the chain.

You can measure the front chainline directly with a simple ruler. Simply hold the ruler against the seat tube or down tube and measure the distance from the middle of the seat tube to the middle of the chainring teeth. In the case of triple chainwheel sets, measure to the middle chainring. In the case of doubles, measure to the halfway point between the two rings. In the photo below, the chainline is about 44 mm. It's easier to see the centerline of the seat tube than in this photo, because the reflection or shadow of the ruler curves away from where the ruler contacts the seat tube. (Or, if you know the diameter of the seat tube you can measure from the side nearest the chainwheel, and add half the seat tube's diameter.)

![]()

![]()

Front chainline may be adjusted either by moving chainwheels, or by moving the crank(s) -- also affecting tread, symmetry of the pedals around the bicycle's centerline, or both.

The list below covers all options, starting with the simpler ones.

If your chainring is mounted on the outside of the spider, you can move it to the right this way. If it's mounted on the inside of the spider, you can move it to the left as shown.

This uses the same 10 mm I.D. spacers normally used on rear hub axles.

Suitable spacers are available in 1, 2, and 3 mm thickness. You may need to use longer "double" stack bolts, especially for the 3 mm size.

You might leave off the outer or inner chainwheel of a double or triple, effectively moving the chainline inward or outward by half the spacing between chainwheels, generally about 2.5 mm. It is quite common to use the two inner positions of a triple crankset as a double, with a chainring protector plate in place of the outer chainring. If converting a double to a single, you could also use chainring spacers as described earlier.

If you go this route to a narrower chainline, make sure that there won't be a clearance problem between the frame and the crank or chainring. With steel frames, it used to be common to add a bit of clearance for the small inner chainring of a triple crankset by a light hammer blow to the right chainstay, using a broom handle to soften and spread the impact. Only do this with a steel frame!

Phil Wood BBs are super quality, available in many different lengths, and they also feature the ability to adjust the chainline over a range of several millimeters.

Phil Wood stuff is expensive, but it's the Very Best.

You need to be careful about crank/axle compatibility if mixing and matching parts. Also see my article about bottom-bracket tapers.

![]()

![]()

To measure rear chainline:

On a bicycle with a sprocket cluster, this is the chainline to the middle of the cluster. With a single chainwheel, this should match the front chainline, to equalize the chain angle for the inner and outer sprockets. With more than one chainwheel, the front chainline could be shifted a few mm inward or outward depending on how the chainwheels are to be used. The article about chainline with derailers covers that topic at length.

![]()

![]()

More about rear chainline adjustment including data on specific hubs may be found in the articles:

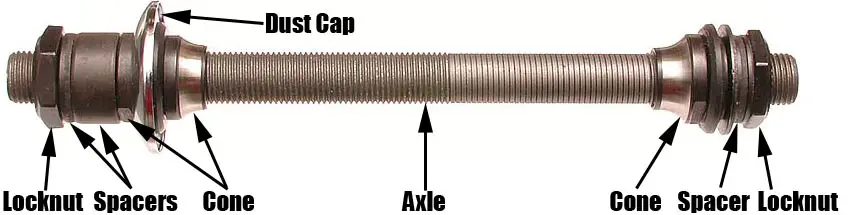

Chainline may be adjusted at the rear wheel by rearranging spacers on the rear axle, and with a steel frame, also by re-spacing the rear dropouts. Adjustable hubs use conventional threaded axles, so you can increase the OLD spacing by removing the locknuts and adding spacer washers, and replace the axle as needed.

If you add equal thicknesses to both sides, the chainline is unaffected, since it's measured from the middle outward.

If you add more spacers to one side, or move them from one side to the other, you can change the chainline, but this will render a double-sided (flip-flop) hub unusable on one side or the other, since you'll be increasing the chainline on one side while decreasing it on the other -- unless you also use a different chainring depending on which way the wheel is inserted.

Moving spacers from one side to the other will disturb the alignment between a disc brake rotor and caliper. Re-spacing a frame will tilt the caliper and cause a slight lateral misalignment. Avoid these modifications unless the brake allows adjustments to compensate for them.

It is also useful when adjusting the chainline of a multi-speed bicycle.

It is almost always possible to add spacer washers on the left side of an internal-gear hub, or in many cases,to remove a washer or use a thinner locknut. Almost all internal-gear hubs are designed so bearings are adjusted only on the left, and many have the driver, or a a rotary shifting mechanism, immediately inside the right dropout. In this case, attempting to adjust or remove parts on the right may result in difficult reassembly or damage. It may still be possible to add a spacer on the right, if there is still enough axle extension to hold the right-side axle nut -- and the bellcrank or "clickbox" which shifts some hubs.

Spacers, if any, are located just behind the outer locknuts, between the locknuts and the cones (or the bearing mounting nuts, if your hub uses cartridge bearings.) You will need cone wrenches and a general understanding of hub bearing adjustment to do this job.

Assuming the rear hub's spacing already matches your frame's spacing, you can take spacer washers from one side of the hub and move them to the other side, thus shifting the entire hub from side to side. In the case of a hub originally meant for a multi-speed freewheel, there is usually a rather thick spacer on the right (freewheel) side of the hub. You can replace this with a stack of thinner spacer washers that add up to the same overall thickness, then distribute the washers from side to side as needed to get the chainline where you need it to be.

Once you have done this, you'll need to re-dish the wheel by adjusting the spokes. This is a bit of trouble, but, in the case of multi-to-single-speed conversion, the re-dishing actually results in making the wheel much stronger than it was.

Also see my article about frame spacing.

Fixed-gear sprockets are usually intended to be installed with the flange facing inward, so the teeth are outboard. However, in many cases, it is possible to flip a fixed-gear sprocket over if you need to move the rear chainline to the left.

These spacers also can be used with freewheels or fixed-gear sprockets, if there is sufficient thread engagement on the hub.

![]()

![]()

![]()

Last Updated: by John Allen