Sheldon Brown's

Bicycle Glossary Sp - Ss

|

![]()

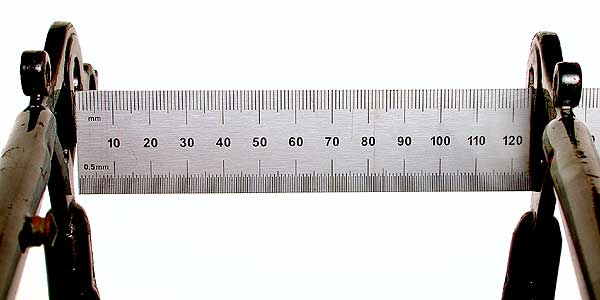

Hubs come with various length axles, but the axle length is not as critical as the overlocknut distance, since it is the locknuts that actually contact the frame ends. Overlocknut distance can't be measured directly without a caliper of some sort.

This frame has a spacing of 125 mm

The dropout spacing of a frame must match the overlocknut distance of the wheels that are to fit it.

Some standard spacings:

| 91 mm | Low-end front hubs. |

| 96 mm | Older front hubs, especially French. |

| 100 mm | Modern front hubs. |

| 110 mm | Rear older track, coaster brake and other single-speed hubs. Also, front hubs for Downhill bikes with 20 mm axles. |

| 114 mm | Rear 3-4-speed . |

| 120 mm | Rear 5-speed, Ultra 6, newer track hubs. |

| 126 mm | Rear 6- and 7-speed (road). |

| 130 mm | Rear 7-speed (MTB) and 8- 9- and 10-speed (road). |

| 135 mm | Rear 7- 8- and 9-speed (MTB) |

| 140 mm | Rear tandem. |

| 145 mm | Rear tandem (newer models.) |

| 150 mm | Retro-Choppers, some Downhill and Freeride models. |

| 160 mm | Rear tandem (new Santana proposed standard.) |

In practice, the axle can be quite a bit shorter than this...even 1-2 mm protrusion past the locknuts will suffice to locate the axle properly, so, when converting a hub to the next wider spacing, it is usually not necessary to replace the axle.

In the case of steel-based frames, it is a fairly minor matter to re-adjust the spacing of a frame to make it fit a different width hub. This process is commonly referred to as "cold setting."

Re-spacing is not generally feasible with aluminum, carbon fiber or titanium frames.

See also my Article on Frame Spacing

| Center-to-center Spacing |

Sprocket Thickness | Spacer Thickness | Total Width | |

|---|---|---|---|---|

| "Regular" 5-/6-speed |

5.3 mm | 1.85 mm | 3.5 mm | |

| Sun Tour "Ultra" 6-speed |

5.0 mm | 1.85 mm | 3.15 mm | |

The above dimensions are approximate. |

||||

| Sun Tour "Accushift" 6-speed |

5.5 mm | 2.0 mm | 3.5 mm | 30 mm |

| Shimano HG 7-speed |

5.0 mm | 1.85 mm | 3.15 mm | |

| Shimano IG 7-speed |

5.0 mm | 2.35 mm | 2.65 mm | |

| SRAM Freewheel 7-speed |

5.0 mm | 1.8 mm | 3.2 mm | |

| Sun Tour 7-speed |

4.8/5.0 mm | 2.0 mm | 3 x 2.8 mm(L) 3 x 3.0 mm(H) |

31.5 mm |

| Campagnolo 8-speed |

5.0 mm | 1.9 mm | 3.1 mm | |

| Sachs 7-speed & 1997 8-speed |

5.0 mm | 1.8 mm | 3.2 mm | |

| Sachs 1998+ 8-speed |

4.8 mm | 1.8 mm | 3.0 mm | |

| Shimano 8-speed |

4.8 mm | 1.8 mm | 3.0 mm | |

| SRAM Cassette 8-speed |

4.8 mm | 1.8 mm | 3.0 mm | |

| SRAM Freewheel 8-speed |

5.0 mm | 1.8 mm | 3.2 mm | |

| Sun Tour 8-speed |

4.8/5.0 mm | 2.0 mm | 3 x 2.8 mm(L) 4 x 3.0 mm(H) |

36.5 mm |

| Campagnolo 9-speed |

4.55 mm | 1.75 mm | 2.8 mm | |

| Shimano 9-speed |

4.34 mm | 1.78 mm | 2.56 mm | |

| SRAM 9-speed |

4.34 mm | 1.8 mm | 2.54 mm | |

| Campagnolo 10-speed |

4.12 mm | 1.7 mm | 2.42 mm | |

| Shimano 10-speed |

3.95 mm | 1.6 mm | 2.35 mm | |

![]()

![]()

For bikes with only one gear shift, it's pretty simple. The number of gears is the number of positions.

The traditional way for designating the number of speeds with such bikes is to multiply the number of rear positions (sprockets) by the number of front positions (chainwheels.)

However, touring and mountain cyclists, with 3 chainrings commonly referred to them as "24 speed."

See also my article on Gear Shifting and my Gear Calculator Page and my Speeds Page.

![]()

![]()

Many newer bottom brackets use splines where the cranks attach to the bottom bracket spindle. Cartridge-type bottom brackets also use a splined wrench to install and remove the bottom bracket unit.

Some frame tubing has internal ribs to reinforce the tube; these are sometimes also referred to as splines.

In this specific context, but only in this context, "Spinning ®" is a registered trademark.

![]()

![]()

A conventional spoke has a swaged head, like the head of a nail, to keep it from pulling through the flange of the hub. Immediately after the head the spoke takes a right-angle bend, also known as the "elbow" of the spoke. (See also straight spokes) The outer end of the spoke is threaded, and a special nut called a nipple fits through the rim and screws onto the spoke threads.

Traditionally, most bicycles have had 36 spokes in each wheel. British bicycles, for years, used to use 40 spokes in the rear, and 32 in the front. This was a better system for the consumer, because the strength of the wheels was in better proportion to the stresses on them. It makes things easier for the manufacturers, however, to use the same number of spokes front and rear. This results in a front wheel that is needlessly heavy, and/or a rear wheel that is not as strong as it should be.

In the last decade of the 20th century, 32-spoke wheels became increasingly common. Manufacturers tout this as an advantage, because it saves a very small amount of weight (they don't mention that it is also cheaper!) For most cyclists, the reduced strength and reparability of 32 spoke rear wheels is a greater detriment than the very tiny improvement in performance they offer.

Formerly, spoke diameters were specified in terms of wire gauge, but the trend is toward specifying the diameter in millimeters.

Spoke length is measured from the inside of the elbow to the very end of the threads, most usually in millimeters.

(courtesy of )

Brand Model Material Diameter Length

(MM)Count Weight

(Grams)Litespeed titanium 2.0 267 32 122 DT Revolution stainless 2.0/1.55 266 32 134 Wheelsmith 1.8DB stainless 1.8/1.55 266 32 135 FiberFlight Æro plastic 266 32 136 Wheelsmith 1.8DB stainless 1.8/1.55 267 32 146 DT 1.8DB stainless 1.8/1.6 266 32 156 DT 1.8 stainless 1.8 266 32 179 Wheelsmith 2.0DB stainless 2.0/1.7 273 28 159 Wheelsmith 2.0DB stainless 2.0/1.7 298 32 182 DT 2.0DB stainless 2.0/1.8 266 32 193 DT 1.8 stainless 1.8 291 16 97 Wheelsmith 2.0 stainless 2.0 264 16 107 Wheelsmith 2.0 stainless 2.0 266 16 109 Wheelsmith 2.0 stainless 2.0 267 32 218 DT 2.0 stainless 2.0 266 32 221 DT 2.0 stainless 2.0 289 16 120 Warning: Fiberflight spokes break and wheels fail catastrophically -- John Allen

(courtesy of )

Brand Gauge/

DiameterMaterial Weight Comments Hi-E 15/1.8 aluminum 0.235 requires special socket wrench Wheelsmith 14/2.0 aluminum 0.344 DT 15/1.8 brass 0.850 old-style disc-shaped DT 14/2.0 brass 1.000 new-style trumpet-shape Wheelsmith 14/2.0 brass 1.063 DT 15/1.8 brass 1.100 new-style trumpet-shape DT 14/2.0 brass 1.140 old-style disc-shaped Fiber Flight 14/2.0 plastic 7g/36 (claimed weight) Warning: Fiberflight spokes break and wheels fail catastrophically -- John Allen

There are also "novelty" or fad lacing patterns, including the "crow's foot" and "snowflake" designs. These patterns are eye-catching, but have no practical advantage.

Spoke patterns are discussed at some length in my wheelbuilding article.

![]()

![]()

A spoke protector is not a necessity on a bike that is well treated, because the derailer can't go into the spokes if it's properly adjusted and if it is not bent. Bicycles which are subjected to rough handling, however, are prone to getting the rear derailer bashed in, and in such a case, the spoke protector can prevent very serious damage.

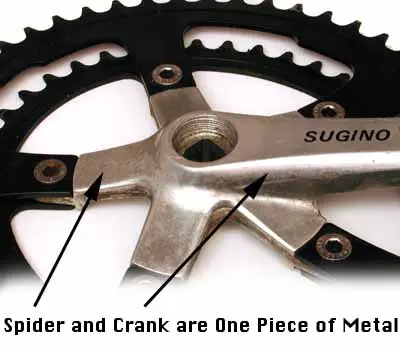

The front sprockets are also commonly called chainwheels or chainrings. The term "sprocket" is perfectly correct to refer to either front or rear, but most adult cyclists use this term mainly to refer to the rear sprockets. The use of "sprocket" to refer specifically to a chainwheel is mainly confined to BMX usage.

The rear sprockets individually are also commonly called cogs or gears; as a group they are referred to as a block, cassette, cluster or freewheel.

The "sprung" weight is the weight of the part of the vehicle and its payload which is held up by the springs. In the case of a suspension-equipped bicycle, the sprung weight includes most of the frame, and the rider. In the case of a rigid-frame bicycle, the "sprung" weight consists of the rider's trunk and head while the rider is off the saddle, carrying his or her weight on bent knees/elbows.

The "unsprung" weight is the weight of the wheels and the parts of the suspension that move up and down with the wheels as they track over bumps.

When a bump lifts a wheel up, the spring compresses. After the wheel passes over the bump, the spring pushes the wheel back down into contact with the ground. In the case of a vehicle with a low sprung/unsprung weight ratio, such as one with heavy wheels and a light rider, the spring will not be able to push it back into contact with the ground as fast as the same spring could push a lighter wheel.

If the rider is light, the spring force will also be light, so it will not be able to push the wheel back down as fast as the stronger spring that would be used with a heavier rider could push the same wheel.

If the rider is light, but the spring is strong, the rider will not get enough benefit from the suspension, and the strong spring will lift the rider as well as the wheel.

The name "SRAM" is an acronym from the initials of the founding partners.

![]()

![]()

![]()

Last Updated: by Harriet Fell