Winner, Winner Pro and Alpha Freewheels

|

|

![]()

![]()

Why? I'll give several reasons.

A wheel with freewheel threading may still be serviceable, and you may wish to keep it in service.

Today's derailer-equipped bicycles have a 130mm or 135mm rear overlocknut distance, to accommodate an 8-9-10 (I'm getting dizzy)- 11-12-sprocket cluster. Most 1980s and earlier derailer-equipped bicycles have 120mm overlocknut distance. Most also have steel frames, and the dropouts can be respaced, but you may want to keep the spacing as is. Many 1980s and 1990s bicycles have 126mm spacing, and the frames are of aluminum, so the dropouts cannot be respaced.

SunTour freewheels work with the 120mm and 126mm overlocknut distance. These freewheels were very common and are very versatile.  There are still enough of them -- and parts -- around to meet the needs of bicyclists who would like to keep an older frame and wheelset in service. You will find these freewheels and sprockets on eBay, or in a local bike shop if it holds onto older components.

There are still enough of them -- and parts -- around to meet the needs of bicyclists who would like to keep an older frame and wheelset in service. You will find these freewheels and sprockets on eBay, or in a local bike shop if it holds onto older components.

Unlike freewheels currently in production, the SunTour freewheels also allow almost any sprocket combination. A SunTour narrow-spaced ("Ultra") freewheel will index with a Shimano derailer and 7-speed shifter -- or with an 8-speed shifter using a bit of alternate cable routing.

The one significant disadvantage of these freewheels over current ones is that the sprockets are not ramped, and so shifting is not as smooth. But, if you want to choose your own gear progression, or your bicycle has less than 130mm spacing, the tradeoff may make sense for you.

I still have, and ride, a couple of bicycles with these freewheels. I have even reground worn sprocket teeth at times to make them work with replacement chains. (See information on regrinding sprockets in our article on freewheels.)

You also may be interested in these freewheels for historical reasons. We have another page about SunTour history, with more background information on these freewheels.

![]()

![]()

All Perfect, Pro-Compe and New Winner bodies can be identified by the stout two-notch freewheel-remover fitting, and by the flange at the back, with four notches corresponding to the four splines on the larger sprockets. Winner Pro/Winner and Alpha bodies have four notches for the freewheel remover. The bodies also are labeled on the outer ring.

Perfect and Pro-Compe freewheel bodies are very similar, except for finish. Perfect bodies are bronze-colored, and Pro-Compe bodies are black. There are five general types, with dimensions as in the table here. Widths given are approximate but are distinct enough to identify the body types.

| Configuration | Width of splines |

Splined sprockets |

Width of threads |

Threaded sprockets |

Overhang |

|---|---|---|---|---|---|

| 5-sp. 5.5mm, 14T min. |

12.8mm | 3 | 11.2mm | 2 | 0 |

| 6-sp. 5.5mm, 14T min. |

18.3mm | 4 | 11.2mm | 2 | 4mm |

| 6-sp. 5mm (Ultra), 14T min. |

16.0mm | 4 | 10.2mm | 2 | 2 to 3mm |

| 6-sp. 5.5mm, 13T min |

12.8mm | 3 | 11.2mm, 5.5mm |

2 + 1 | 0 |

| 6-sp. 5mm (Ultra), 13T min. |

11.2mm | 3 | 10.2mm, 5mm |

2 + 1 | 0 |

SunTour Pro-Compe freewheel for Ultra spacing, with 2mm overhang, 14T minimum.

Pro Compe freewheel that takes a 13t sprocket

Classic European freewheels have an odd number of ratchet teeth and two pawls directly opposite one another, so only one pawl engages at a time. Some Perfect and Pro Compe bodies have an even number of ratchet teeth and two pawls directly opposite one another. As you turn the freewheel slowly backwards, you can hear it go ttick-ttick-ttick as the two pawls engage at (nearly) the same time. Unless the freewheel's bearings are adjusted just short of binding, chain pull rocks the outer body one way, then the other as the wheel turns, making a light clunk-clunk noise. The outer ring of Perfect and Pro Compe freewheels has a tendency to unscrew, probably worsened by this excess motion. If the clunk-clunk noise starts or gets worse, check right away whether the outer ring is coming loose. Twice I have had one come off completely, dumping all the bearing balls out of the freewheel. Both times, I managed to ride home after screwing the outer ring back on, taking care not to coast.

The freewheel can be restored with about 100 new 1/8" bearing balls -- but as the saying goes, an ounce of prevention is worth a pound of cure. Disassembly of a freewheel body usually makes no sense, but this is the exception. Every time I have rebuilt one of these freewheel bodies, I have found that removing one of the two paper-thin shims under the outer ring leaves the bearings in perfect adjustment. Instructions are in our article on rebuilding freewheels. You do not have to disassemble the freewheel completely to make this modification.

The New Winner body is cleverly designed to take 5 or 6 sprockets in 5.5mm spacing; 6 or 7 sprockets in 5mm spacing. The outer sprocket can be as small as 13 teeth with 6 sprockets, or 12 teeth with 7 sprockets. New Winner bodies have an adjustable lockring rather than shims and generally were supplied in correct adjustment. Two of the special tools shown below, now rare, are used to disassemble or adjust the New Winner body, but this work is very rarely necessary. You may be able to get by with one of these tools and a chain whip, with the freewheel body mounted on a wheel, but two are needed for convenience of bearing adjustment.

New Winner bodies exist in two forms: early and late. Early models have bodies machined from a solid block of steel and have squared notches for the large sprockets. Late type have a shaped body (forged or cast), are slightly lighter and have deeper, curved grooves for the splined sprockets. These late bodies accept older Perfect and Pro Compe sprockets without modification.

Not easily obtainable but usually unnecessary: SunTour New Winner tool

The Winner Pro/Winner body is much like the New Winner body. "Winner Pro" was used when a sprocket cluster with wide spacing was built up, "Winner", with narrow ("Ultra") spacing, but the bodies are interchangeable. The only difference are internal: the Winner Pro has dust seals. Differences from the New Winner body:

Note that there was an earlier model also called "Winner." It was 5-speed only, and could take a 13T outer sprocket.

The Alpha body (image at the left) was much like the Winner and Winner Pro; It used the same 15-spline middle sprockets, but it could not take threaded ones in the middle position. It used one more splined sprocket -- note the longer section for the 15-spline sprockets. The threading diameter for the outermost sprocket was different, 40mm, the same as for the rare Pro Compe body that takes a 13T sprocket. Whether the thickness of the sprocket's flange is the same, we find out when we take our one Pro Compe of that type apart to compare!

![]()

![]()

SunTour Perfect sprockets are bronze-colored, Pro-Compe sprockets are gold, sometimes silver, and New Winner sprockets, silver. These freewheels use four-spline large sprockets, and threaded smaller ones. The teeth are 2mm thick. Sprockets from an earlier-model Winner(not covered here) are black or gold, some are slightly thinner, and some have eight splines rather than four. The middle sprockets of the newer Winner and Winner Pro have 15 splines, and may be sliver or black.

The photo below shows the sprockets and spacers for the common 5-speed Perfect freewheel. Sprockets with integral spacers are installed with the spacer toward the next larger sprocket. Sprocket teeth are beveled. The shorter side of the teeth should face the next larger sprocket, as shown. If a sprocket is installed with the sorter side of the teeth facing outward, shifting will be very poor.

Dimensions are as in the table below. The diameter given is for the freewheel body. The inside diameter of threaded sprockets is about 1/2 mm smaller than the outside diameter of the threads to which they attach.

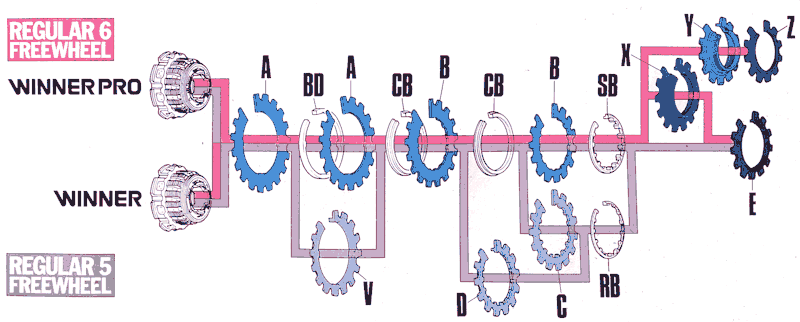

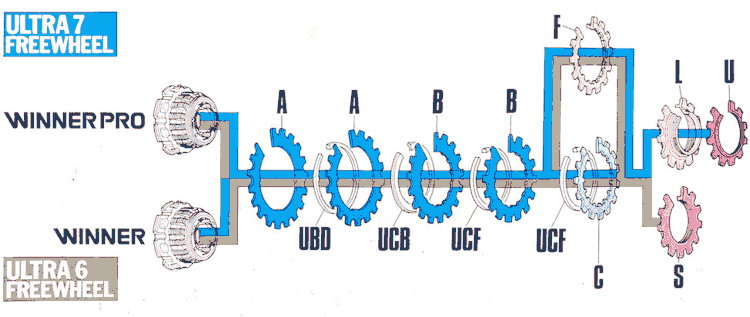

All sprockets that work for the Winner Pro body also work with the Winner body. See diagrams, below.

| Type | Code | Use with: |

Body/ threading diameter |

smallest sprocket |

largest sprocket(s) | Notes |

|---|---|---|---|---|---|---|

| 4-spline flat | A | All | 52mm | 17 | 17-28,30, 32,34,38 |

File splines of Perfect sprockets to use on Pro-Compe or New Winner body. |

| 4-spline, integral spacer |

V | 5.5mm spacing | 52mm | 16 | 3.5mm spacer for wide (5.5mm) spacing |

|

| 4-spline, integral spacer |

5.0mm spacing | 52mm | 16 | Includes 2.7mm spacer for Ultra (5.0mm) spacing. Not used on New Winner or Winner Pro, so no code. | ||

| threaded | R | All | 44mm | 15 | 21 | Has wide threading flange to secure splined sprockets on New Winner narrow-spaced 6 and 7-speed. |

| 15 spline, flat |

B | Winner/Pro | 44mm | 15 | 23 | Short splines |

| threaded | T | All | 44mm | 15 | 19 | May not have wide threading flange to secure splined sprockets on New Winner narrow-spaced 6 and 7-speed. |

| 15 spline, flat |

C | Winner Pro 5.5 mm spacing |

44mm | 15 | 17 | long splines |

| threaded, integral spacer |

N | 5.5mm spacing | 44mm | 14 | Includes 3.5mm spacer | |

| 15 spline, integral spacer |

D | Winner Pro 5.5mm spacing |

44mm | 14 | Long splines; includes 3.5mm spacer | |

| threaded, integral spacer |

P | 5.0mm spacing | 44mm | 14 | Includes 2.7mm spacer for Ultra spacing (but 3.5mm will work on Pro Compe) | |

| 15 spline, integral spacer |

F | Winner Pro, 5.0mm spacing |

44mm | 14 | Long splines; includes 2.7mm spacer | |

| threaded | Perfect; Alpha? | 40mm | 13 | 14 | Used on the rare Perfect body with two threading diameters. Shimano 600 or Dura-Ace sprocket will work. Alpha outer sprocket is similar, maybe the same. |

|

| threaded | X | New Winner, |

39mm/ 39mm |

14 | 16 | 6-speed wide. Outer sprocket threads onto this one. |

| threaded | E | New Winner, Winner Pro |

39mm |

13 | 14 (15 in later catalogs) |

For 6-sp wide, threads onto X sprocket; For 5-sp, outer sprocket attaches to body. |

| threaded | S | New Winner, Winner Pro |

39mm | 13 | 14 | 6-speed narrow outer sprocket, attaches to body |

| threaded | L | New Winner, Winner Pro |

39mm/ 35mm |

13 | 15 | 7-speed second-outermost sprocket. Outermost sprocket threads onto this one. |

| threaded | Y | New Winner, Winner Pro |

39mm/ ? |

13 | 15 | 7-speed second-outermost sprocket. Outermost sprocket threads onto this one. |

| threaded | U | New Winner, Winner Pro |

35mm | 12 | 13, 14 in later catalogs | 7-speed outer sprocket attached to next sprocket. Shimano Uniglide or track sprocket threading is slightly smaller, won't work. |

| threaded | Z | New Winner, Winner Pro |

? | 12 | ? | 7-speed outer sprocket attached to next sprocket. |

All threaded sprockets have built in spacers. So do the smallest ones in each splined position, permitting them to be used without the chain's riding up on a spacer.

![]()

![]()

Let's look at the photo of sprockets and spacers of the common 5-speed Perfect freewheel again. Because of the different spacings and numbers of sprockets, Perfect and Pro Compe freewheel bodies were made in several splined, threaded and total widths. Spacers of different widths established the different sprocket spacings.

The spacer behind the outer, 15-tooth sprocket is special, beveled to avoid interfering with the chain.

The two leftmost spacers, between the splined sprockets, are 3.5mm thick and the sprockets are 2mm thick, for a combined spacing of 5.5mm. The outer spacers are only 1.9mm thick because the outer, threaded sprockets are thickened near the center hole for the threads. 14-tooth threaded sprockets and 16-tooth splined sprockets have integral full-width spacers. The 15-tooth threaded sprocket uses a special, beveled spacer, as already mentioned and as shown. Splined sprockets with 17 or more teeth are flat and use separate spacers, as shown. Ultra spacing uses thinner spacers. The table below identifies the different spacers.

| Type | Use with body |

Inside diameter |

Outside diameter |

Thickness | Notes |

|---|---|---|---|---|---|

| Spline | All with 5.5mm spacing |

52mm | 57mm | 3.5mm | Steel, split ring |

| Spline | All with (nominally) 5mm spacing |

52mm | 57mm | 2.7mm | Steel, split ring, or plastic, with 4 splines |

| transition | New Winner | 52mm | 56mm or 58mm |

0.9mm | Used in Ultra New Winner where the second splined sprocket does not overhang the end of the splines. |

| transition/ threaded |

All | 44mm | 54mm | 1.9mm | For 5.5mm sprocket spacing. Beveled spacer must be used behind a 15T sprocket |

| transition/ threaded |

All | 44mm | 52mm | 1.1mm | For 5.0mm sprocket spacing. Beveled spacer must be used behind a 15T sprocket |

Except for the 16-tooth sprockets, in two widths with integral spacers, all four-spline sprockets are interchangeable, though Perfect sprockets have slightly deeper, rounded splines which may have to be filed before they will fit a Pro Compe or New Winner body. Most 44mm threaded sprockets are fully interchangeable too. 14-tooth sprockets came with two widths of integral spacers, as indicated in the table. Using an outermost 14-tooth 44mm-threaded sprocket for 5.5mm spacing on an Ultra-spaced freewheel works OK except on the New Winner 6- and 7-speeds, where it would reduce the spacing to the next outer sprocket.

The outer one or two New Winner and Winner Pro sprockets use a threading different from other SunTour sprockets, and so sprocket availability may determine whether you will want to use a New Winner or Winner Pro body. Only the two innermost positions take splined sprockets, making a good sprocket progression with large sprockets hard to assemble -- but we have a workaround, keep reading.

The image below shows 5 kinds of special New Winner/Winner Pro outer sprockets and gives their threading diameters. The E sprocket is attached to the X sprocket to make a 6-speed, and directly to the body to make a 5-speed. The Y and Z sprockets attach to the body like the E and X,but the Z sprocket has a smaller threading diameter and can go as low as 12 teeth. The U and L sprockets are used together to build a 7-speed.

The letter codes for New Winner combinations provide a nice mnemonic:

The SunTour Winner Pro/Winner body shape and sprocket positioning were the same as those of the New Winner, except that the middle threaded sprockets could be replaced by sprockets with 15 splines. Some spacers also were different, as shown in the illustrations below.

The next photo shows a Perfect body with three splined sprockets and two spacers in place. The red arrow points to one of the splines. The rightmost splined sprocket overhangs the larger-diameter section of the freewheel body, as shown, so that the spacer behind the next, threaded sprocket can secure the splined sprockets.

Perfect and Pro-Compe bodies designed for the narrower Ultra (nominally 5mm) spacing have a splined section to accommodate three or four sprockets and their narrower spacers. With some Ultra-spaced freewheels, paper-thin shims are needed in addition to the regular spacers so that the rightmost splined sprocket overhangs the splines and the threaded sprockets secure the splined ones.

With Ultra (nominally 5mm) spacing, the second-largest sprocket does not overhang the splines of the New Winner body, and so a special 0.9mm thick spacer allows the threaded sprockets to secure the splined ones, as shown in next photo. To engage this narrow spacer, the leftmost threaded sprocket has to have a wide flange.

5mm spacing is nominal. It can be slightly smaller between the larger, splined sprockets, especially thinner ones, This can result in uneven spacing. If a freewheel has additional paper-thin spacers, these space the larger sprockets slightly farther apart, keeping spacing even where an outer sprocket screws up against a shoulder on the body. Even spacing is most important if an indexed shifter is used.

When building up a SunTour freewheel, it is helpful to have an ample collection of spacers salvaged from disassembled freewheels. Sutherland's Handbook for Bicycle Mechanics, 6th Edition -- still available as a CD-ROM -- includes a complete listing of the different sprockets and spacers. Yellow Jersey (see link at the end of this article) has reprinted SunTour's manual which includes this information for Winner and New Winner freewheels.

The New Winner body takes only two splined sprockets, and threaded sprockets were sold only in sizes up to 21 teeth, requiring a big jump in size between sprockets if the splined sprockets are large. (Evidently, SunTour thought of the Winner series as for racers.) An aftermarket adapter to allow a splined sprocket in the third position was available once -- no longer -- but there is a workaround. The 15-tooth threaded sprocket's flange fits neatly into the opening in a splined sprocket with flat-top splines, and can be tack-welded onto the inside face of the larger sprocket (the side where the teeth are shorter), also serving as a spacer. The welds must not extend higher than the face of the smaller sprocket. Grind the welds down if necessary.

Winner Pro and later Winner freewheels allowed a 23T sprocket in the third position.

Splined sprocket modified into a threaded sprocket.

outside face of sprocket | inside face of sprocket

Freewheel and cassette bodies are designed so the rear derailer will clear the spokes with the smallest possible sprockets. With larger sprockets, the slant of the spokes allows an additional sprocket closer to the wheel. A dished sprocket, or one bolted onto the innermost splined sprocket, can be added without increasing wheel dishing or dropout spacing.

A dished sprocket will move the other sprockets 2 mm farther to the right, and can allow a body which was designed for 5.5 mm sprocket spacing to accommodate an additional sprocket in 5 mm (Ultra) spacing. Dishing a sprocket requires the use of a machinist's tool -- an arbor press -- and a forming template of 1/8" or 3 mm sheet metal with a round hole in the middle. The part of the sprocket which is to be bent should first be heated red hot to soften it and allowed to cool slowly, otherwise the hardened steel may crack. Avoid overheating the teeth.

For my Cannondale bicycle with 126 mm dropout spacing, I built up a 7-speed Ultra-spaced freewheel with the largest sprocket dished, on a Pro-Compe 6-speed body. Because the sprocket is dished, the wheel dishing is more moderate than it would normally be, and so the wheel is stronger. More about this issue is in another article.

Thanks to Yellow Jersey bike shop for review of this article, and an article with more information about SunTour freewheels, including models not covered in this article.

![]()

![]()

Last Updated: by John Allen