Sheldon Brown's

Bicycle Glossary Bo - Bz

|

![]()

Common 5-bolt double-chainwheel sets use 130 mm or 110 mm diameters.

Modern triple chainwheel sets have two diameters, a large one for the two outer chainrings, and a smaller diameter, with a separate set of bolts, for the granny ring.

Full-size triples usually use 110 mm/74 mm, or 130 mm/74 mm for newer "road triples." Campagnolo uses 135 mm/74 mm. Compact triples commonly use 94 mm/58 mm.

"C-C" is the distance between adjacent stack bolts.

This is usually easier to measure directly than the actual Bolt Circle Diameter.

Measuring BCD: This 110 mm BCD ring measures 64.7 mm center-to-center

(or, from left side to left side, or right side to right side --easier to measure).Multiplying this dimension by 1.701 will give you the actual BCD for a 5-bolt chainring. Use 1.155 for 3-bolt chainrings.

If there is an even number of holes, diameter can be measured directly unless something is in the way -- usually, the crank. Then measure at two adjacent bolt holes, and multiply by 1.414 for 4-bolt chainrings and 2.000 for 6-bolt chainrings.

For dimensions of specific models, see my Bicycle Crank/Chainring Bolt Circle Diameter Crib Sheet.

If the threads do extend full length, technically it is a "screw " but only pedants insist on this distinction.

A very few high-end hubs actually do use bolts, usually with an Allen head. Among these are American Classic, Bullseye, Phil Wood and White Industries.

![]()

![]()

Boneshakers existed before the invention of Dunlop's pneumatic tire, and had wooden or iron wheels, with iron or (later) solid rubber tires. This caused them to provide a very harsh ride, hence the name.

The boneshaker evolved over time into the high wheeler, with the drive wheel getting larger and larger, the rear wheel shrinking down.

Some misguided souls use this term to describe the keel tube of a tandem frame. This makes no sense semantically. It probably arose because somebody couldn't think of one of the several more descriptive terms, and picked something cute-sounding out of the air. It is to be hoped that this foolish term will disappear into the dustbin of history.

A "brake booster" is a metal bridge that connects the outer ends of the two cantilever bosses, holding them in position and greatly reducing their tendency to flex under load. A booster resembles an inverted "U", as it curves up and over the tire.

Many things may be used to boot tires, including leather, currency, food wrappers, etc. Patches intended for tube patching will not usually do a good job, because they are stretchy and will blow through the hole just as an inner tube would.

The best material for boots is a piece cut from an old thin-tread tire, preferably a tubular. Many cyclists carry such a piece of tire for this purpose.

A boot does not need to be glued in place. It will be held in position by the pressure of the inner tube.

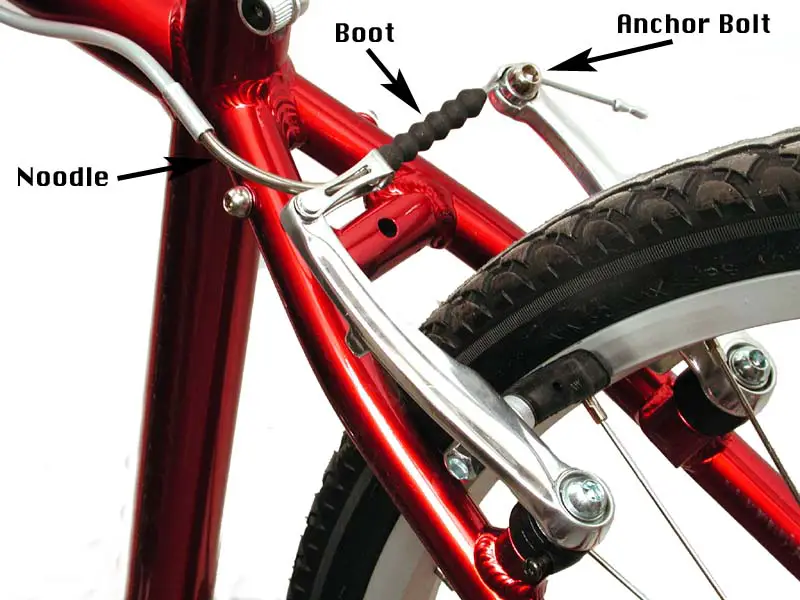

An accordion-like rubber sealing device to cover the connection where one part slides into another, preventing dirt from entering.

An accordion-like rubber sealing device to cover the connection where one part slides into another, preventing dirt from entering.

This type of "boot" is commonly seen on the legs of suspension forks, and on the cables of direct-pull cantilever brakes.

![]()

![]()

| A conventional cup-and-cone bottom bracket. The lockring wrench is about to loosen the lockring, the pin wrench is engaging two of the holes in the adjustable cup | A cartridge bottom bracket. The splined tool is shown above the bottom bracket. The crank would need to be removed to actually use the tool. | Old American-style "Ashtabula" One-piece Crank Bottom Bracket The lock nut and the cone behind it have a left-hand thread . |

|

|

|

|---|

Bottom brackets come in different sizes, according to the nationality of the frame. The table below is for threaded bottom-brackets. For the Ashtabula and other unthreaded bottom brackets, see the unthreaded bottom-bracket cribsheet.

| Standard: | Threading | Adjustable (left) cup/cone direction |

Fixed (right) cup/cone direction |

Shell Width |

Applications/Notes |

|---|---|---|---|---|---|

| British I.S.O. |

1.370" X 24 tpi 1.375" X 24 tpi |

right | left | Standard 68 mm O.S. 73 mm |

The overwhelming majority of bicycles in current production. British and I.S.O. are interchangeable. |

| Shimano Hollowtech II, FSA MegaExo, RaceFace X-type | ISO | right | left | 90 mm, 95 mm including cups | External cups for cartridge bearings fit British/ISO threaded bottom brackets or unthreaded shell. 24 mm spindle, spacer to use 6805 bearings with 25mm I.D.. Bottom bracket shell must be faced so cups are parallel. |

| Campagnolo Ultra-torque | Italian or ISO | Spindle diameter 25mm. | |||

| Chater Lea | 1.450 x 26 TPI | right | left | Obsolete British size but available from Phil Wood & Co. | |

| French | 35 mm X 1mm (25.4 tpi) | right | right (wrong!) |

68 mm | Obsolete, used on older French bicycles. Prone to problems due to the right-threaded fixed cup, which tends to unscrew itself in use. |

| ISIS Overdrive I | 48 x 1.5 mm | right | left | 68mm 100 mm |

|

| ISIS Overdrive II | 48 x 1.5 mm | right | left | 68mm 100 mm |

New proposed standard oversized system. |

| Italian | 36 mm X 24 tpi | right | right (wrong!) |

70 mm | Italian and some high-end French bicycles. Prone to problems due to the right-threaded fixed cup, which tends to unscrew itself in use. |

| Phil Wood American Isis (comments) | 50 mm | right | left | 1.5 mm thread pitch. | |

| Raleigh | 1 3/8" X 26 tpi | right | left | 71 mm 76 mm |

Older British-made Raleighs, 3 speeds and others from the Nottingham factory. |

| Swiss | 35 mm X 1mm (25.4 tpi) | right | left | 68 mm | Same thread as French, but fixed cup is left- threaded for reliability. |

| Bottom Bracket Shell Threading (Below) |

BritishI.S.O. 1.37/1.375" x 24 tpi CUPS R-L (34.8/34.9 x 1.06 mm) |

Italian 36 mm X 24 tpi CUPS R-R (1.417" x 1.06 mm) |

French 35 mm X 1mm CUPS R-R (1.378 x 25.4 tpi) |

Swiss 35 mm X 1mm CUPS R-L (1.378 x 25.4 tpi) |

Raleigh 1 3/8" X 26 tpi CUPS R-L (34.9 x 1.06 mm) |

|---|---|---|---|---|---|

| British/I.S.O. 1.37/1.375" x 24 tpi (34.8/34.9 x 1.06 mm) |

Made to Fit | 36 mm Cup diameter is too large, thread won't even start. | Cup diameter is slightly too large, usually won't start. Right (fixed) cup threaded in the opposite direction. |

Cup diameter is slightly too large, usually won't start. |

Diameter matches, but thread pitch does not.

Will bind after only a few threads are engaged. |

| Italian 36 mm X 24 tpi (1.417" x 1.06 mm) |

British/I.S.O. cups fall through | Made to Fit | Italian shells are larger diameter, all other size cups fall right through, threads will not engage. | ||

| French 35 mm X 1mm (1.378 x 25.4 tpi) |

35 mm = 1.378". Shell is slightly larger, thread pitch slightly finer. Left side may seem to fit, but will be loose. |

36 mm Cup diameter is too large, thread won't even start. | Made to Fit | Left (adjustable) side is interchangeable. Right (fixed) side is threaded in the opposite direction, won't fit. |

35 mm = 1.378". Shell is slightly larger, thread pitch slightly coarser. Left side may seem to fit, but will be loose. |

| Swiss 35 mm X 1mm (1.378 x 25.4 tpi) |

35 mm = 1.378". Shell is slightly larger, thread pitch slightly finer. May seem to fit, but will be loose. | 36 mm Cup diameter is too large, thread won't even start. | Left (adjustable) side is interchangeable. Right (fixed) side is threaded in the opposite direction, won't fit. |

Made to Fit | 35 mm = 1.378". Shell is slightly larger, thread pitch slightly coarser. May seem to fit, but will be loose. |

| Raleigh 1 3/8" X 26 tpi (34.9 x 0.977 mm) |

Diameter matches, but thread pitch does not.

Will bind after only a few threads are engaged. |

36 mm Cup diameter is too large, thread won't even start. | Cup diameter is slightly too large, usually won't start. Right (fixed) cup threaded in the opposite direction. |

Cup diameter is slightly too large, usually won't start. | Made to Fit |

| Application | Dimension | Notes |

|---|---|---|

| Track/Coaster Brake Traditional One-Speed Most internal gear hubs |

40.5-42 mm | Older bikes with 110 spacing would be on the smaller end of this range Newer bikes with 120 mm spacing normally use 42 mm |

| Road Double | 43.5 mm | Shimano spec, measured to the midpoint between the rings. with typical 5 mm chainring spacing, this puts the inner at 41 mm, the outer at 46 mm. |

| Road Triple | 45 mm | Shimano spec, measured to the middle ring. |

| Singlespeed MTB Alternate |

47.5 mm | White Industries ENO hubs use this chainline, which lines up with the middle position of a typical MTB triple. It's also fairly close to the outer position of a typical "road" double. |

| MTB Triple | 47.5-50 mm | Shimano spec, measured to the middle ring. 47.5 preferred, but for frames with oversized seat tubes, the longer dimension may be needed, because the fat tube places the front derailer mechanism farther to the right. SRAM standard chainline is 49mm with 142mm OLD and thru axle |

| Singlespeed and Single-chainwheel MTB, "Boost 148" | 52 mm | Wider chainline need for chainstay clearance on newer MTBs, typically with disc brakes and 148 mm OLD spacing This is close to the chainline of the outer ring of a typical MTB triple. |

| Rohloff Speedhub | 54 mm (58 mm w/13 tooth) |

Sprockets are proprietary, threaded. All except the 13-tooth may be flipped over to double wear life. |

| Freeride and Downhill | 55 mm | Newer Freeride and Downhill bikes with 150 mm spacing |

| Tandem | about 60 mm | Tandems with 160 mm spacing |

| Fatbike | 66 mm | Fatbikes with 170 mm spacing |

| Fatbike | 76 mm | Fatbikes with 190 mm spacing -- needed with 4.8" (125 mm) wide tires. |

Standard bottom-bracket bearing assemblies are specified in terms of width of the bottom bracket shell (generally 68, 70 or 73 mm) and the length of the spindle (102 - 130 mm.)

Current usage generally assumes that 68 and 73 mm bottom bracket units are for British/ISO threaded frames, and that 70 mm units are for Italian threaded frames.

The spindle length mainly depends on what kind of crankset you'll be using, and doesn't have much to do with the frame. New cranks come with a spec sheet that lists what length spindle they are intended to be used with. Sometimes two lengths are listed. When this is the case, the longer size is for use on frames with fat seat tubes, because such frames put the front derailer mechanism farther to the right than on a frame with a standard seat tube.

See also my article on Bottom Bracket Sizes for information on matching spindles to cranks.

See also my article on Bottom Bracket Tapers.

My Tool Tips series includes related articles on Cottered, and Cotterless crank removal, as well as tools for disassembly and adjustment of cup-and-cone bottom brackets.

![]()

![]()

In the bicycle industry, the best frames have traditionally been made by very small-scale, custom or semi-custom framebuilders.

There are also small-scale makers of premium or super-premium parts, companies such as Chris King, E.A.I., Phil Wood , White Industries and a few others. These small, high-prestige manufacturers often (but not always) make products superior to those of the big manufacturers. For instance, Chris King headsets are the very best, and Phil Wood hubs and bottom brackets are unequalled.

Unfortunately, the "boutique" category also includes a lot of other companies who produce overpriced, inferior products, or sometimes just slap a prestigious name on generic Asian imported stuff.

Boutique hubs are often sold on the basis of light weight, but that's often a bit of a scam. Boutique hubs are generally sold without quick release skewers, while major-brand hubs come with skewers. This has two negative effects:

Major brand hubs have forged bodies, making the spoke flanges considerably stronger.

"Boutique" hubs are often marketed as if they were an upgrade from, say, run-of-the-mill Shimano hubs, but in fact they are generally inferior in quality to genuine Shimano hubs! (The only hubs that I consider actually superior to Shimano are Phil Wood, and they typically cost at least three times as much as Shimano.)

These wheels are basically throw-away items, intended to be used for a season or until they get damaged, then replaced with a new set.

There was a famous legal case arising from Bowden's cables. He licensed many manufacturers to make cables based on his patent, but failed to exercise quality control over the licensed products that bore his name. As a result, the patent and trademark were deemed to have been abandoned, and became public domain. (I am not a lawyer, I heard this from a lawyer some time ago, I don't vouch for the accuracy of the legal information...)

The differences depend on the handlebar type they are to be used with, and on the amount of cable travel required:

Levers for drop ("road" "racing") handlebars curve toward the handlebar, to follow the curvature of the handlebar. These levers have mounting clamps to fit the 23.8 mm (15/16") diameter of almost all drop handlebars.Levers for upright ("mountain" "cruiser" "BMX") handlebars mount on a straight section of the handlebar, and the lever curves away from the bar for better clearance. These levers have mounting clamps to fit the 22.2 mm (7/8") diameter of almost all upright handlebars.

Standard pull levers are designed to work with caliper brakes or traditional centerpull cantilever brakes.Long pull levers are designed to work with "direct-pull" cantilever brakes, such as Shimano "V-Brakes" ®

Direct pull cantilevers have twice as much mechanical advantage as traditional brakes, so they require a lever with half as much mechanical advantage. Long pull levers pull the cable twice as far, but only half as hard.

Mismatched Lever Issues:

Old short-pull lever, new direct pull ("V type") cantilever

The excessive mechanical advantage of this combination will make it difficult to modulate the brake, and it may be all too easy to lock up the wheel.The lever feel will be very soft and mushy.

The lever will travel too far before engaging the brake, and it may bottom out against the handlebar. Thus, the brake may be super-powerful at first, but as the brake shoes wear, the lever's bumping up against the handlebar will prevent full application. This is likely to be a particular problem in wet conditions.

New long-pull lever, old caliper or traditional cantilever

The reduced mechanical advantage will require unusually high hand strength to get barely adequate braking force.Most disc brakes are designed for long-pull levers, but discs designated as "road" models are usually compatible with traditional short-pull levers.Paradoxically, the lever will feel very solid, the brake will engage with a very short amount of lever travel...but won't actually be squeezing very hard on the rim.

There are stepped pulley devices to permit mixing otherwise incompatible levers/brakes. The best known is the QBP Travel Agent ®.

![]()

![]()

Brass is also easy to cast, and has been used for derailer parts and quick-release skewer acorn nuts, and for thrust washers in caliper brakes. Various special brass alloys are used as filler material for brazing.

See also welding, fillet brazing.

This is a French word, variously translatable as "diploma," "certificate" or "patent."

Petersen, a hard-core cyclist, marched to a "different drummer" than most of the industry. He introduced many innovations to the market, and also strongly resisted other trends and innovations that he didn't approve of. He is now the head of Rivendell Bicycle Works.

Bridgestone bicycles are something of a cult item now. This site includes a whole subsection on Bridgestone bikes.

Sometimes the term is (somewhat inappropriately) applied to damaged headset races.

The load is reduced to 500kg for very soft materials, and the steel ball is replaced with tungsten carbide for very hard materials. Substantial section thicknesses are required to ensure that the test is "valid", that is, edge effects or gross section deformation remain negligible.

As a standardized test, the procedure is very useful in industrial settings, primarily as a quality-control tool. In common steels, as a rule-of-thumb, BHN 515 is approximately equal to the ultimate tensile strength.

The test is useless in the context of bicycles since almost no part of a modern bicycle would survive intact the effect of a 10 mm ball at 3000 kg and no part of a bicycle is sufficiently massive to ensure a "valid" test.

The BHN number, albeit a very useful tool in manufacturing, is not a satisfactory physical constant nor is it applied to design. Also, the BHN number is not reproducible under nonstandard ball diameters and loads unless geometric similitude is maintained.

Other hardness tests have largely replaced the Brinell test.

(This definition contributed by John Fox)

Also known as "Four cross" or "4X" Mountain bike riders compete on a specially designed highly-challenging course. The races last between 25 seconds and one minute and are usually fast and frenzied. The courses are a mix of natural and man-made obstacles covering a steep descent.

The array of obstacles includes triples, doubles, table tops, step ups, drop offs, bermed or off-camber corners and gap jumps. The difficulty of getting over these obstacles at high-speed whilst being jostled by three other competitors means that there are plenty of crashes. The 4X competition starts with a limited number of riders competing in knock-out rounds.

The knock-out rounds can be decided by a series of heats called 'Motos' with riders competing three times before moving on to quarters, semis and final. The final consists of the last four riders left in the competition.

Matt Andrews

Bull Moose HandlebarA style of handlebar popular on early mountain bikes. The handlebar and stem are a single unit, with the stem splitting in two at the quill and attaching to the handlebar at two points, forming a triangle. |

|

Some writers have objected to this term being applied to spokes, and maintain that "swaged" is more correct, since the operation that produces a butted/swaged spoke is one of thinning the middle, not thickening the ends. For some reason, these writers don't generally object to the use of "butted" in reference to tubing, though the process is also one of thinning the middle, not thickening the end. This objection is based on a misunderstanding of the origin of the origin of the term "butted." "Butted" means having a butt, i.e. a thick end, and has no reference to the means of fabrication.

![]()

![]()

![]()

Last Updated: by Harriet Fell